compression test cell|Compression Testing Fundamentals : Brand manufacturer Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using . webO número de série tem o seguinte formato: XXXX-XXXX-XXXX-XXXX-XXXX-XXXX-XXXX-XXXX. Deve copiar e adicionar este número de série ao seu Nero ControlCenter para .

{plog:ftitle_list}

WEBWatch Bbw Gs porn videos for free, here on Pornhub.com. Discover the growing collection of high quality Most Relevant XXX movies and clips. No other sex tube is more popular .

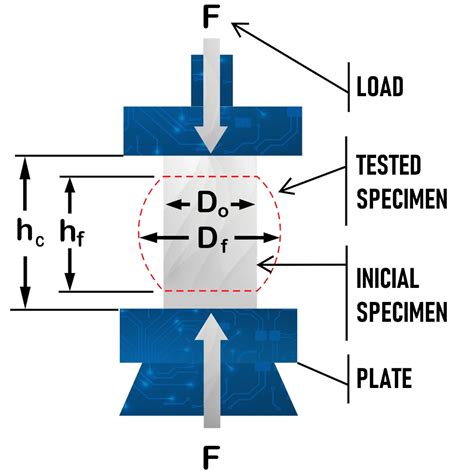

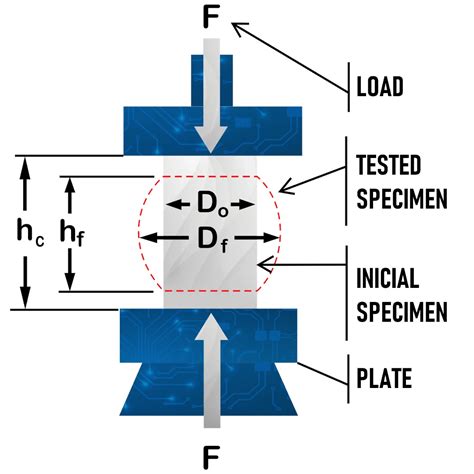

Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using .Compression testing is a type of mechanical testing that involves applying a compressive force to a material and measuring its response. The compressive force tends to reduce the size of the material, and the test is designed to .

Compression testing is key in materials science for evaluating how materials respond to compressive loads. It helps determine mechanical properties like stiffness, strength, and fatigue life. This overview covers the testing process, material properties, standards, . Quality control in manufacturing and engineering relies heavily on compression force testing to determine material strength, durability, and stability. This article highlights the key uses and equipment needed for such testing.A compression test is a mechanical test that determines how a material such as aluminum or plastics behaves under a compression or crush force. The output of a compression test is a test report that characterizes compressive properties . Interface compression load cells are used in OEM and test and measurement . The compressive strength of materials and structures is important to engineers. Load cells measure the pushing force of an application on a .

What is Compression Testing?

Compression Testing: How to Put the Squeeze on Materials for

In compression testing, the sample or the component is compressed between two moving platens. A load cell and an extensometer or strain gauge are used to measure load and displacement. Compression tests are useful for testing material or component load-bearing .

A compression test will help determine a material’s compressive yield strength, modulus and deflection under load—all characteristics that are critical to know.Compression tests measure the load and displacement of a material under crushing pressure, determining its strength and allowing for the calculation of compressive stress and strain, which can be represented as a stress-strain .

Compression Testing: Exploring Methods,

A compression test is always a good way to determine if the symptoms you’re experiencing are related to internal engine damage. However, if compression is found to be low inside the engine, significant repairs or in .In precision measurement, understanding the weight of an object is often paramount. Here, a compression load cell shines, a device expertly calibrated to translate weight or force into readable data. Specially created to bear the burden of compression rather than tension, these load cells provide accurate and reliable readings in environments where pressure is key.Load Cell: The load cell measures the force applied to the specimen. It typically uses strain gauges that convert the force into an electrical signal, which is then read and recorded by the machine’s control system. . How is a compression . Agriculture: Farmers use compression load cells in automated systems to measure the amount of feed being dispensed to livestock. This ensures animals are fed the right amount, improving health and productivity. Automotive Testing: Car manufacturers use these load cells to test the weight and balance of different vehicle parts. This testing .

Compression Testing Fundamentals

Thinner than a credit card, these force sensors fit into narrow spaces to measure the applied load between two surfaces. While they’re less accurate than larger alternatives such as load cells and handheld force gauges, these will fit almost anywhere. Place them within an industrial press to make sure it’s operating in a safe range, or form them to the contour of a forklift seat to test .During triaxial testing, a cylindrical soil sample is enclosed in a rubber membrane and placed within a cell, commonly made of glass or plastic. The sample within the cell usually has a length/diameter ratio of 2, while it is subject to a confining pressure, applied on all sides by compression of the fluid (usually water) that fills the chamber .Our force load cells include compression and tension load cells for test and measurement applications. TE offers load cells in standard and custom designs. TE offers packaged load cell assemblies for test and measurement applications that require high performance or .Load Cell The load cell is a transducer that measures the force applied to the test specimen. Instron load cells are accurate down to 1/1000 of load cell capacity. Compression Platens A wide variety of compression platens and other compressive fixtures are available to accommodate test specimens of different materials, shapes, and sizes.

The unconfined compression test is the most popular method of soil shear testing because it is one of the fastest and least expensive methods of measuring shear strength. It is used primarily for saturated, cohesive soils recovered from thin-walled sampling tubes. . Without applying confinement, place the triaxial cell above the sample .A load cell, an actuator, and a frame to support the specimen make up the device. The specimen is subjected to a controlled, axial force by the machine. . Compression test findings are examined to ascertain the material’s compressive strength, compressive modulus, and deformation characteristics, among other mechanical parameters. . High Precision Load Cells: Ensure accurate measurement of compressive forces. Digital Display: Provides real-time data on force and deformation. . Understanding Box Compression Test Results Interpreting the results from a box compression test is crucial for improving packaging designs. The key parameters typically assessed include:

Download scientific diagram | Compression test of the open-cell foam: (a) experimental setup; (b) image of foam surface taken by digital microscope; (c) strain-stress curve of 10 cycle test (A . The challenge to applying a full-cell compression test is the high force level. According to our previous experience, the mechanical strength of various cells at the moment of failure occurrence is approximately 120 MPa. So, axial compression of pouch cells with 85 mm (length) × 50 mm (width) can reach 510 kN; that for 230 mm × 150 mm is 4140 .

Compression Testing Basics

Superior Micro-Scale Mechanical Test Machine. Enhanced for smaller samples, the MicroTester offers improved force resolution, streamlined test setups, and exceptional visual feedback. It’s ideal for a wide range of applications, from tiny tissue samples to testing the properties of hydrogel microspheres, cell spheroids, and engineered .

combustion gas leak detector

A compression test measures a cylinder’s ability to hold pressure as the piston moves up and down. Mechanics use an oscilloscope and observe the stored pattern as the engine spins when performing a dynamic .A conventional triaxial compression test is conducted on a sample of dense sand. The void ratio was 0.60, and the cell pressure was 200 kPa. The initial sample height was 70 mm, and the cross-sectional area was 10 cm2. The .

Compression load cells also offer long-term stability, and this stability and accuracy can be further ensured with regular load cell calibration services offered by companies such as HBK. The ease of measurement with a compression load cell helps to speed up processing and output, reducing the time spent obtaining results and ultimately .

flue gas analyser calibration london

36 ILD Open-Cell Poly Foam. Compression strength is evaluated through a test called Indentation Load Deflection (ILD), also known as Indentation Force Deflection. This is a computer controlled performance evaluation, with standardization allowing all materials tested using this process to be measured against each other on a balanced plane .A cylindrical rock specimen is placed in a specifically designed cell (such as a Hoek cell). A specially designed membrane is attached to the cell so that it remains airtight. . The Unconfined Compression Test is a laboratory test used to derive the Unconfirmed Compressive S. Splitting Tensile Strength Test (Brazilian) Aug, 10, 2020 . Fig. 10(d) shows a deformed cell RVE test specimen after the in-plane compression test. The cell RVE specimen after the compression test shown in 10(d) is one of the three cell RVE specimens tested. Note that a different tested specimen is shown in Fig. 4. The specimen showed here has a fairly regular buckling pattern and was selected for .

1. An unconsolidated-undrained triaxial compression test was performed on a 2.80-in diameter specimen of saturated clay. A confining (cell) pressure of 20 psi was used. At failure, the load applied through the piston was 20 lb. (a) Determine the undrained shear strength (c) of the clay. Express your answer in both psi and psf.

the cell is used to sense the tension in the steelyard rod connecting the lever system to the beam. Typical capacities range from 100 lb to 50,000 lb for tension canisters, and 25 lb to 20,000 lb for S beams. 3.3.2. Figure 6 illustrates a compression canister cell; Figure 7 illustrates a low profile compression disk cell,A compression load cell is designed to measure pushing or squashing forces, making it unidirectional and solely focused on measuring downward compression. Typically, a compression load cell is installed underneath the object to be measured or weighed. In contrast, tension load cells are often capable of measuring both tension and compression. When using the bioamine GG in neuronal cell culture, it was noted that the neural cells prefer a surprisingly high elastic modulus . (TA Instruments), and digital filtration at 1 Hz was used to reduce the noise in the load signal. The compression test parameters (displacement rate, starting point, friction) were varied to gain a complete view .A standard specimen of cohesionless sand was tested in triaxial compression test and the sample field at a deviator stress of 450 KN/ sq-m, when the cell pressure was 100 kN/sq-m under drained condition.

Unconfirmed Compressive Strength (UCS) stands for the maximum axial compressive stress that a specimen can bear under zero confining stress. Due to the fact that stress is applied along the longitudinal axis, the Unconfined Compression Test is also known as Uniaxial Compression Test. UCS is a parameter widely used in geotechnical design, but .This test is a modification of the SML test and takes only about one-third of the SML test duration. Although the test is faster, the IE test was reported to provide similar correlations to the SML test (Fellenius, 1975). The IE test is conducted by applying increments of 15% to 25% of the design load and maintaining that load for about 10 minutes.

land flue gas analyzer

lancome flue gas analyzer

webElephant Bet is operated by MOTA, TAVARES & BARROS SA - NIF 5417259144 - Licence N° B20081200360166654683/ISJ/MF/20

compression test cell|Compression Testing Fundamentals